Accelerate Beam Processing Using

StruCIM's Job Automator

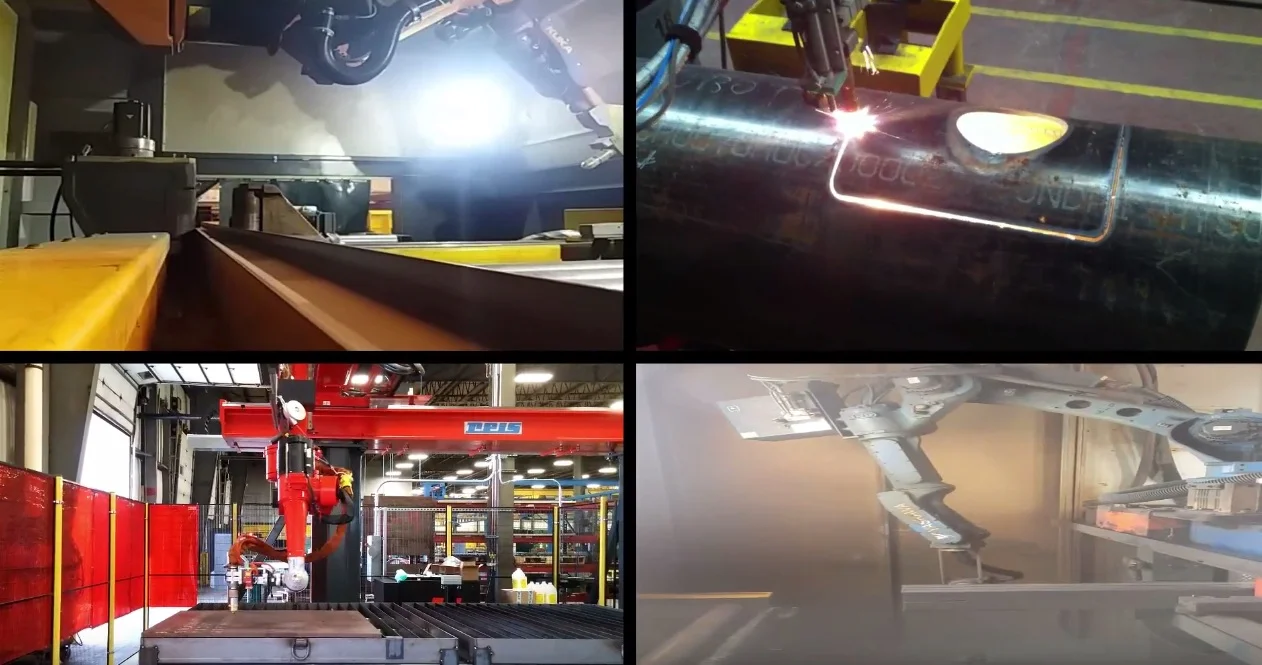

Fabrication jobs can benefit from the automated batching and optimization of assemblies for beam cutting. StruCIM's Job Automator helps speed through large batches of DSTV files and creates tightly nested beams that will result in less scrap and more production time spent producing perfect parts.

A complete folder of DSTV parts are loaded then organized from the assembly information into a table of part specs. Complete cutting paths are computed, the optimal grouping of parts are computed and the paths for the robot plasma cutting system are automatically created.

Load all job DSTV files into one comprehensive table

Create useful reporting of all job specs

Total beam count

Total job weight

Number of blanks/stock material required

Sort beams by profile

Nesting for reduction of scrap

Full programming for rules-based cutting

Channels, H-Beams, Square Tubes, Clip Angle Flat Plate

Other popular profiles

Direct download to all popular controllers

Kuka/Motoman/ABB/Reis/Fanuc/Kawasaki